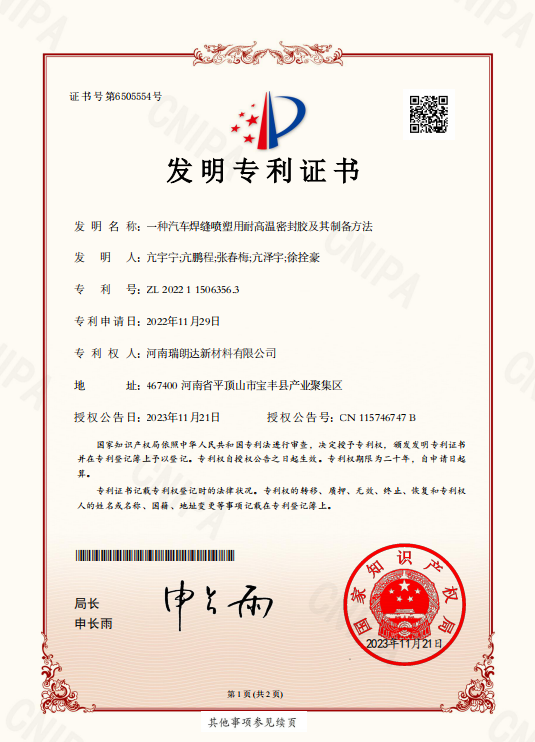

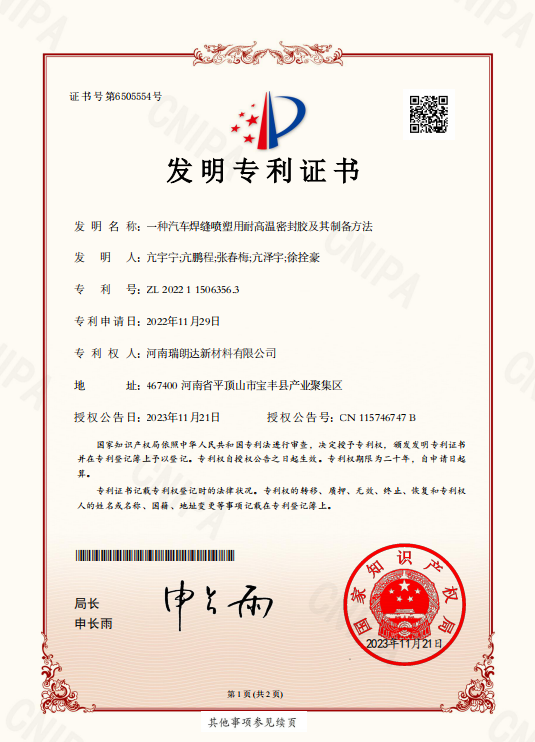

Ruilangda has once again achieved technological innovation in the field of automobiles and vehicles. Recently, the company obtained a new national invention patent authorization, patent name: A high-temperature resistant sealant for automotive weld spraying and its preparation method, patent number: ZL 2022 1 1506356.3

Ruilangda has once again achieved technological innovation in the field of automobiles and vehicles. Recently, the company obtained a new national invention patent authorization, patent name: A high-temperature resistant sealant for automotive weld spraying and its preparation method, patent number: ZL 2022 1 1506356.3

In surface coating technology, the coating process is divided into spray painting process, spray plastic process, and metal powder spraying process according to the different coatings used. The paint produced by the spray painting process has disadvantages such as high organic solvent content and environmental friendliness. Spray coating technology is a coating method that uses solvent-free 100% solid powder as a coating. Its working principle is to spray plastic powder onto the surface of the workpiece through an electric field to form a plastic coating. After high-temperature baking, the plastic particles melt into a dense protective layer, which tightly adheres to the surface of the workpiece. The spray coating process does not require diluents or primers, is environmentally friendly, and has the advantages of good coating performance, diverse and efficient, high yield, and recyclability. It is widely used for surface coating of automotive parts, guardrails, transformers, distribution cabinets, fitness equipment, household appliances, etc.

At present, the national policy encourages the use of spray painting technology, and newly started automobile projects are also required to adopt spray painting technology. Automotive body weld sealant can provide sealing, anti-corrosion and other functions, and is an essential body adhesive in automotive manufacturing. Polyvinyl chloride resin is widely used in the field of vehicle body weld sealant due to its excellent elasticity, weather resistance, corrosion resistance, and low-temperature flexibility. Due to the high temperature baking required for the spray coating process, approximately 220-280 ℃, the weld sealant must be resistant to high temperatures. However, polyvinyl chloride resin has the disadvantages of poor thermal stability and easy yellowing of color. Therefore, there is an urgent need to develop a high-temperature resistant and non yellowing weld sealant for spray coating to meet its usage requirements.

This invention successfully overcomes these shortcomings and provides an eco-friendly, fast bonding adhesive with good flexibility, adhesion, high temperature resistance, and spray adhesion performance for automotive weld spraying through formula innovation. It solves the technical problems of existing polyvinyl chloride sealants not being resistant to high temperatures and hanging and yellowing under high temperatures. It is a practical adhesive for automotive weld sealing< br />

豫公網(wǎng)安備41042102000091號

豫公網(wǎng)安備41042102000091號

豫ICP備14028033號

豫ICP備14028033號