-

-

Two-component rubber repair agent

HY987 rubber repair agent has excellent properties such as semi flowability, high viscosity, and high strength. Quick rubber repair agent is widely used for repairing and pre protective coatings of cables, rubber liners, rubber rollers, impellers, feeding troughs, etc.

- Product1

& nbsp; & nbsp; HY987 rubber repair agent has excellent properties such as semi flowability, high viscosity, and high strength. Quick rubber repair agent is widely used for repairing and pre protective coatings of cables, rubber liners, rubber rollers, impellers, feeding troughs, etc.

nine hundred

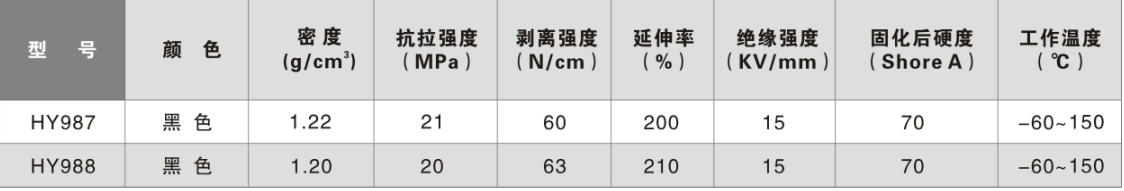

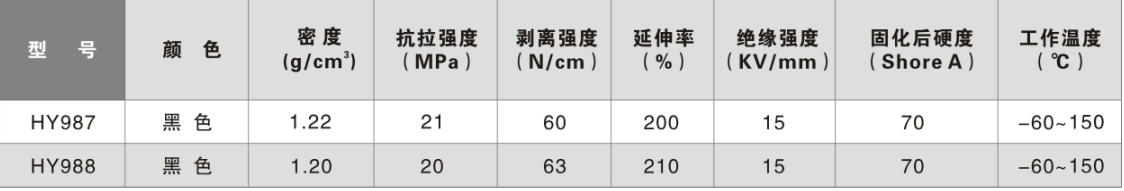

& nbsp;& nbsp;& nbsp;& nbsp; Rubber repair agent product performance

nine hundred and one

< br />

& nbsp;& nbsp;& nbsp;& nbsp; Rubber repair agent packaging specifications

& nbsp;& nbsp; 400g (component A+component B) is one set, 15 sets/box< br />

& nbsp;& nbsp;& nbsp; Rubber repair agent operation process

& nbsp;& nbsp;& nbsp; 1. Surface treatment: Use an angle grinder or wire wheel to roughen the repaired area and its surroundings, and remove any debris. If repairing belt holes or longitudinal tears, a groove needs to be cut, and the adhesive leakage on the back should be adhered with adhesive tape< br />

& nbsp;& nbsp;& nbsp; 2. Cleaning: Clean the surface to be repaired with HY755 cleaning agent or acetone, and let it dry< br />

& nbsp;& nbsp;& nbsp; 3. Glue repair: Mix components A and B in one go (or in a ratio of AB=3:1) and stir thoroughly for 1-2 minutes to ensure complete mixing. Then pour it into the area to be repaired or brush it onto the pre protected area, and smooth it out< br />

& nbsp;& nbsp;& nbsp; 4. Curing: At 25 ℃, it becomes elastic in 1 hour and can be turned on for use< br />

& nbsp; Precautions for rubber repair agent

& nbsp;& nbsp;& nbsp; 1. Keep the container sealed before mixing, and once opened, use it up as soon as possible< br />

& nbsp;& nbsp;& nbsp; 2. The prepared repair agent should be used up within 2 minutes< br />

& nbsp;& nbsp;& nbsp; 3. Store in a cool and dry place, sealed, with a shelf life of one year.

nine hundred

& nbsp;& nbsp;& nbsp;& nbsp; Rubber repair agent product performance

nine hundred and one

< br />

& nbsp;& nbsp;& nbsp;& nbsp; Rubber repair agent packaging specifications

& nbsp;& nbsp; 400g (component A+component B) is one set, 15 sets/box< br />

& nbsp;& nbsp;& nbsp; Rubber repair agent operation process

& nbsp;& nbsp;& nbsp; 1. Surface treatment: Use an angle grinder or wire wheel to roughen the repaired area and its surroundings, and remove any debris. If repairing belt holes or longitudinal tears, a groove needs to be cut, and the adhesive leakage on the back should be adhered with adhesive tape< br />

& nbsp;& nbsp;& nbsp; 2. Cleaning: Clean the surface to be repaired with HY755 cleaning agent or acetone, and let it dry< br />

& nbsp;& nbsp;& nbsp; 3. Glue repair: Mix components A and B in one go (or in a ratio of AB=3:1) and stir thoroughly for 1-2 minutes to ensure complete mixing. Then pour it into the area to be repaired or brush it onto the pre protected area, and smooth it out< br />

& nbsp;& nbsp;& nbsp; 4. Curing: At 25 ℃, it becomes elastic in 1 hour and can be turned on for use< br />

& nbsp; Precautions for rubber repair agent

& nbsp;& nbsp;& nbsp; 1. Keep the container sealed before mixing, and once opened, use it up as soon as possible< br />

& nbsp;& nbsp;& nbsp; 2. The prepared repair agent should be used up within 2 minutes< br />

& nbsp;& nbsp;& nbsp; 3. Store in a cool and dry place, sealed, with a shelf life of one year.