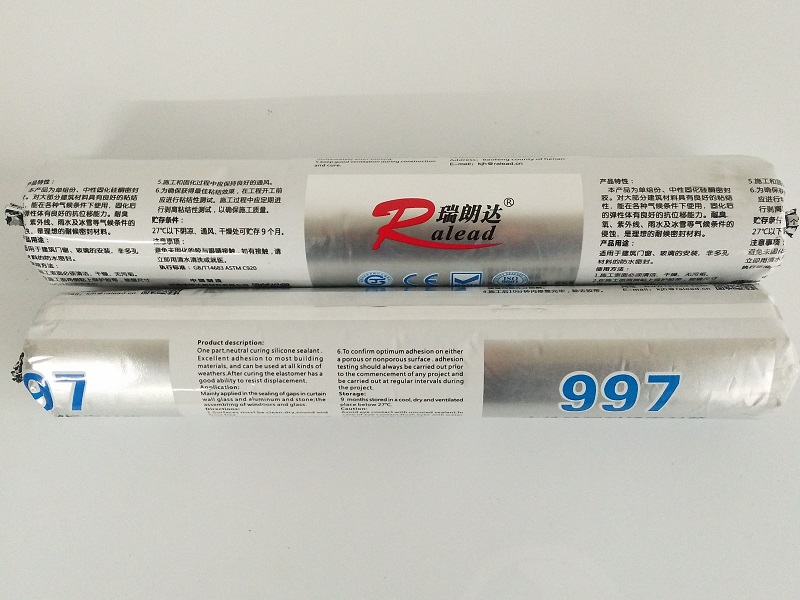

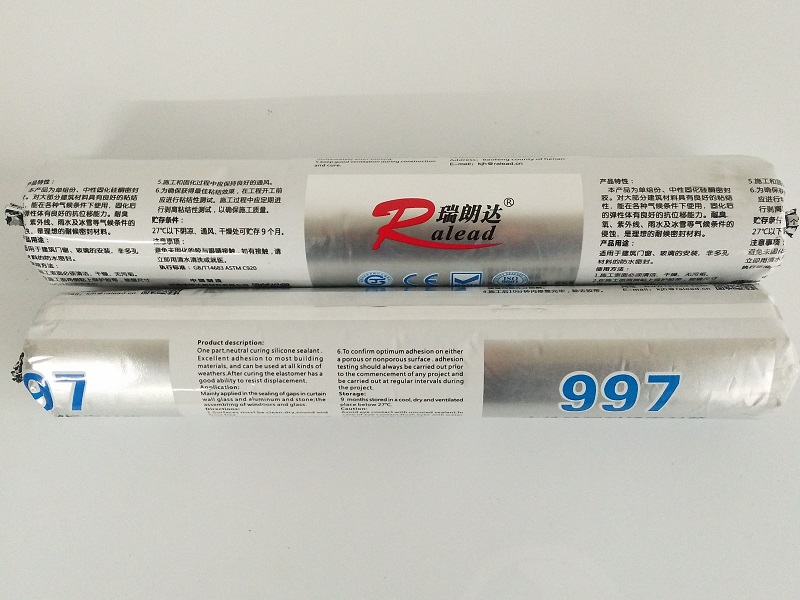

Silicone glass adhesive is a type of silicone product. Silicone glass adhesive is divided into two types, single component and two-component, mainly used for sealing insulating glass. Two component silicone glass adhesive is a room temperature vulcanized two-component sealant mainly composed of room temperature vulcanized silicone rubber 107 and methyl silicone oil 201, with metal oxide as the vulcanizing agent. After curing, the adhesive has excellent weather resistance and UV resistance, as well as high and low temperature resistance and aging resistance; Has high adhesive bonding strength; Has good adhesion to glass and aluminum alloys.

& nbsp; & nbsp; Silicone glass adhesive is a type of silicone product. Silicone glass adhesive is divided into two types, single component and two-component, mainly used for sealing insulating glass. Two component silicone glass adhesive is a room temperature vulcanized two-component sealant mainly composed of room temperature vulcanized silicone rubber 107 and methyl silicone oil 201, with metal oxide as the vulcanizing agent. After curing, the adhesive has excellent weather resistance and UV resistance, as well as high and low temperature resistance and aging resistance; Has high adhesive bonding strength; Has good adhesion to glass and aluminum alloys. Mainly used for sealing the second layer of insulating glass. Next, the sealant manufacturer will introduce the usage method of silicone glass adhesive to you! Let's learn together< br />

& nbsp; & nbsp; Use

& nbsp; & nbsp; Single component silicone glass adhesive can be used immediately, and it is easy to remove it from the bottle with a glue gun, and its surface can be trimmed with a spatula or wood chips< br />

& nbsp; & nbsp; Adhesive time:< br />

& nbsp; & nbsp; The curing process of silicone adhesive develops from the surface inward, and the surface drying time and curing time of silicone with different characteristics are not the same (please refer to the "Technical Parameters" in Chapter 4 for detailed explanation of curing time). Therefore, if surface repair is necessary, it must be carried out before the glass adhesive surface dries (acidic adhesive, neutral transparent adhesive should generally be within 5-10 minutes, and neutral variegated adhesive should generally be within 30 minutes). If using color separation paper to cover a certain area, after applying glue, be sure to remove it before the outer layer is formed< br />

& nbsp; & nbsp; Curing time:< br />

& nbsp; & nbsp; The curing time of glass adhesive increases with the increase of bonding thickness. For example, a 12mm thick acidic glass adhesive may take 3-4 days to solidify, but within about 24 hours, a 3mm outer layer has already cured. When bonding glass, metal, or most wood, it has a peel strength of 20 pounds per inch after 72 hours at room temperature. If the area where glass glue is used is partially or completely sealed, the curing time is determined by the tightness of the seal. In a sealed place, it is possible to remain uncured forever. If the temperature is increased, the glass glue will soften. The gap between metal and metal bonding surfaces should not exceed 25mm. Before using the bonded equipment in various bonding situations, including sealed conditions, a comprehensive inspection of the bonding effect should be conducted. During the curing process of acidic glass adhesive, a smell will be generated due to the volatilization of acetic acid. This smell will disappear during the curing process and there will be no odor after curing< br />

& nbsp; & nbsp; Adhesive bonding:< br />

& nbsp; & nbsp; A. Completely wipe the metal and plastic surfaces clean, remove oil stains, and then use sandpaper to polish the rubber surface, except for rinsing the entire surface of the plastic with acetone first, and then wipe it with acetone. Please follow the precautions for using acetone solvent< br />

& nbsp; & nbsp; B. Apply glass glue evenly on the surface of the prepared object. If you want to bond two surfaces together, you can first position one side and then apply enough force to squeeze out the other side to expel air, but be careful not to squeeze out the glass glue< br />

& nbsp; & nbsp; C. Place the bonding device at room temperature and wait for the glass adhesive to cure< br />

& nbsp; & nbsp;& nbsp; Sealing:< br />

& nbsp; & nbsp; When using silicone glass adhesive for sealing, the same steps should be followed: forcefully squeeze the glass adhesive into the joint surface or gap to ensure full contact between the glass adhesive and the surface< br />

& nbsp; & nbsp; Cleaning:< br />

& nbsp; & nbsp; Before the glass adhesive is cured, it can be wiped off with a cloth strip or tissue. After curing, it must be scraped off with a scraper or wiped with solvents such as xylene and acetone< br />

& nbsp; & nbsp; Attention:< br />

& nbsp; & nbsp; Acidic glass adhesive releases irritating gases during the curing process, which can have irritating effects on human eyes and respiratory tract. Alcoholic neutral adhesive releases methanol during the curing process. Methanol has potential carcinogenic hazards and is a known skin and respiratory allergen. Volatile gases can cause inflammation of the eyes, nose, and throat. So it should be used in a well ventilated environment, avoiding eye contact or prolonged skin contact (after use, wash hands before eating or smoking), and should not be swallowed. Do not allow children to come into contact with it; The construction site should have good ventilation; If accidentally splashed into the eyes, rinse with clean water and seek medical attention immediately. The fully cured glass adhesive poses no danger< br />

& nbsp; & nbsp; General guidelines:< br />

& nbsp; & nbsp; Before use, please carefully read the correct construction method and use of glass glue, and pay attention to the instructions on safe use and related health hazards< br />